MANUFACTURING PROCESS OF CAMEL BRAND WHOLE WHEAT CHAKKI ATTA

-

PRE-CLEANING

-

FINE CLEANING

-

CONDITIONING

-

MILLING

-

SANITISING

-

PACKAGING

PROCESS 1

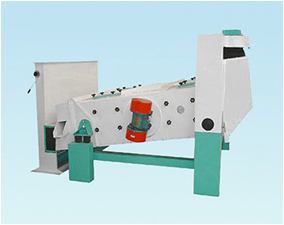

VIBRO SEPARATOR

Firstly we start with the cleaning process of the grains. The wheat is reached to the Vibro separator through a bucket elevator. It is used to classify the large as well as small impurities from the wheat by means of shape and size. This grain cleaning machine is used before the bulk storage of wheat.

Features-

-

Efficient cleaning of grains.

-

With two sieves the machine can remove both coarse and fine impurities.

-

It adopts a low maintenance design the screen can be replaced quickly.

-

A sturdy design reduces wear and tear.

EMERY

- This machine helps to remove the dust of wheat. It is operated on a motor and the hopper is mounted at one end.

- The roller with emery rotates inside the screen. Passing through the screen impurities gets removed

- The processing effect of the machine can be from outside by means of a slide control device.

DE- STONER

This product helps to effectively separate pebbles/stones, glasses, and other high-density impurities in wheat thereby cleaning the wheat. There are two layers of the destoner with different functions. The upper layer can separate impurities and raw materials, and the lower layer can remove impurities such as stones, glass, and so on.

FEATURES OF DESTONER

-

Excellent separation efficiency can effectively remove a variety of stones from a large number of grains to ensure an ideal cereal cleaning.

-

Excellent separation of high-density impurities, such as stones and glasses and metal impurities, effectively reduces the wear and tear on the equipment of the next production process.

-

A wide range of applications, the destoner can be applied to the cleaning and processing of grain such as wheat, barley, buckwheat, barley, and millet.

PROCESS 2

FINE CLEANING

DAMPNER

This machine is normally used just before the grain milling process for the water being sprayed on the wheat in a small percentage in order to soften the grain hull. This machine makes the wheat more elastic and in short, makes grain breakage easier without crushing the bran

Features:

- Efficient water mixing in the grain

- Controlled moisture addition

- Highly effective and durable

- Low in maintenance

- Low power consumption

- Fitted with self-lubricating NTN bearings.

SOURER

It is an important machine in the wheat milling industry. It works in multi-fold aspects. It helps the removal of skin dust and also making the surface of the kernel rough for better and fast penetration of moisture in the dampening process.

FEATURES OF HORIZONTAL WHEAT SCOURER

-

The wheat scourer can efficiently remove impurities that are attached to grain, such as dust, sand grains, etc. Make preparation for the grinding process.

-

Reduce the number of microorganisms (bacterium, epiphyte, etc.) and significantly improve the health safety of grain.

-

The drum sieve and the beating pleat are manufactured with high-quality stainless steel and carbon steel which helps to ensure that the quality is reliable and reduces the maintenance cost.

-

The wheat scourer has a compact and simple design, easy to operate and maintain.

ASPIRATIONAL CHANNEL

Aspiration channel is used for the removal of lightweight particles such as immature shriveled grain, dust, etc. from all kinds of grains and pulses. The maximum cleaning action is obtained by installing a good aspirator after the scourer, seed cleaner, dehusking, etc. Industrial Aspiration channel Machine is particularly suited to separate husks, chaff, small seeds, insect fragments, broken, and hollow kernels.

Salient Features of Aspiration Channel Machine:

-

Compact steel construction body.

-

Low power consumption.

-

Easy installation.

-

Total separation of dust and unwanted materials.

CONDITIONING

Wet Storage- After the cleaning of the wheat, here comes the conditioning part under which the wet wheat after dampening is stored in wet storage tanks and given rest for 6-8 hours for the Softening and conditioning of wheat and getting it ready for the grinding process.

PROCESS 4

MILLING

CHAKKI GRINDING

-

We have the best and latest Choyal Grinding Machines for the grinding of wheat.

-

Black Emery Grinding Stones.

-

Black Stones of siz3 33/30 black emery stones to flourish the quality of the flour.

-

We have installed 8 sets of chakki grinding machines accounting for the production of 2.4 tons of flour per hour.

PNEUMATIC

-

The pneumatic machine is the main equipment during the process of flour milling.

FEATURES OF PNEUMATIC

-

The pneumatic is designed for two parts, the upper part adopts steel material and the under part adopts an iron base.

-

The feeding system of the pneumatic can be moved out completely which makes it easier to fix and maintain thanks to its integrated design. The feeding system can also be driven separately for roller distance adjustment and the roller is highly sensitive for adjustment.

-

The motor is designed inside and saves the floor space.

-

The pneumatic has an electrostatic spraying surface, the color last longer and reduce corrosion.

PLANSIFTER

Plansifter is used for flour grading. Different quantities of silos and sieves are being selected to meet various application requirements. The flour plansifter contains three parts: a central drive unit and two lateral cabins hosing the sifting channels.

FEATURES OF PLANSIFITER

-

The plansifter has the characteristics of large screen size, easy to clean, and low maintenance cost.

-

The plansifter is made of high-quality steel plate, high intensity and durable, the technology of aluminum alloy patent technical sieve has the characteristics of high precision, long service life without deformation.

-

The cleaning part can clean up every corner of the sieve to ensure the safety and sanitation of the equipment.

-

Channels of the flour plansifter are separated to prevent the material from mixing together.

PACKAGING

-

BOPP PACKAGING- It is superior quality packaging used by us which is very durable so the product can last for a very long time.

-

Keeps the product fresh and healthy.

-

We use BOPP packaging because of its strength and capacity to hold weight without breaking easily.

-

Camel whole wheat chakki fresh atta is available in 10kg packaging. 5kg and 20kg are available on demand.